Strong. Precise. Built for Performance.

DMLS is an advanced metal 3D printing technology that uses a high-powered laser to fuse fine metal powder layer by layer—creating fully functional, high-strength metal parts directly from digital files. At [Your Company Name], our DMLS service unlocks the ability to manufacture complex, end-use metal components with superior mechanical properties and exceptional accuracy.

Why Choose DMLS?

-

Production-Grade Metal Parts: Print with industrial-grade metals like Stainless Steel, Titanium, Aluminum, Inconel, and more.

-

High Strength & Density: Comparable to traditionally manufactured metal parts—suitable for demanding environments.

-

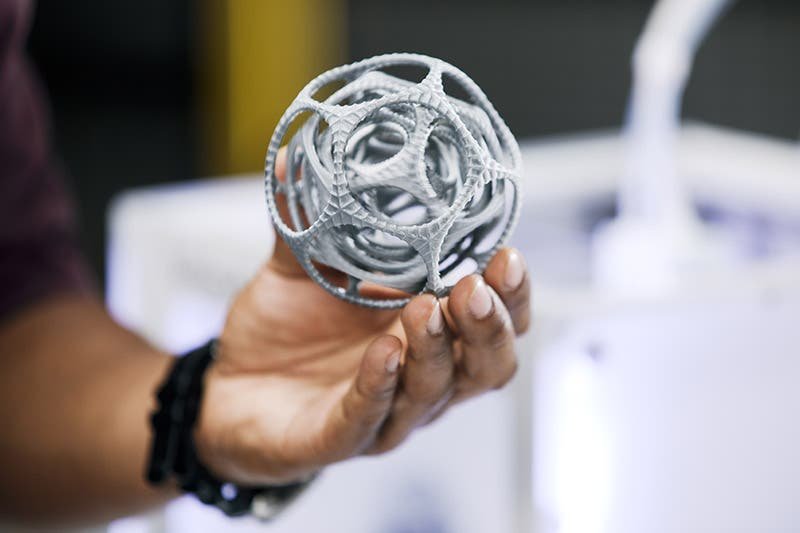

Complex Geometry Freedom: Create internal channels, lattice structures, and shapes impossible with conventional machining.

-

Rapid Iteration & Tool-Free Manufacturing: Ideal for functional prototyping and low-volume production without the need for molds or tooling.

-

Engineering-Grade Precision: Achieve tight tolerances and excellent surface detail, ready for post-processing if needed.

Ideal Applications:

-

Aerospace & Automotive Components

-

Medical Implants & Surgical Tools

-

Heat Exchangers & Engine Parts

-

Tooling Inserts & Custom Fixtures

-

Lightweight Structural Parts

-

High-Performance Prototypes

From mission-critical aerospace parts to custom-engineered tools, DMLS delivers the strength, detail, and innovation modern industries demand.